Why High-Security Fencing Matters in Oil and Gas Fields

How Security Fencing Keeps Important Sites Safe

Oil and gas fields are a big deal worldwide. They pump out resources that keep factories running and homes warm. Keeping these places safe is a must. Any trouble there can mess things up far and wide. High-security fencing steps up as the first wall against risks. It protects the site and keeps everything humming along. Chain link fencing gets a lot of love for this job. It’s tough and bends to fit different needs. People like how it holds strong while letting them see through it to keep an eye on things.

Putting security fencing in the right spots around oil and gas fields guards the pricey gear. It also stops eco-trouble that could pop up if someone sneaks in. Pairing it with stuff like cameras or alarms makes the whole setup even tighter.

Making Oil and Gas Fields Safer with Solid Borders

Safety’s huge in oil and gas work. These places deal with risky stuff and heavy tools all the time. Strong fencing around the edges cuts down on random or sneaky break-ins. Take chain link fences—they’re a go-to pick. They stand up to rough weather without falling apart. The wire mesh in them comes from galvanized or PVC-coated steel. It’s twisted into a diamond pattern. That setup fights off rust, so it’s great for outside.

Plus, solid borders block outsiders from wandering into no-go zones. This drops the odds of accidents or someone messing things up on purpose. Setting clear lines with tough fencing helps make a safer spot for workers and crew.

Stopping Break-Ins and Wrecking

Letting just anyone into oil and gas fields is bad news. It could mean theft, busted stuff, or even sabotage. High-security fencing puts up a hard stop. It scares off trespassers and marks out where people shouldn’t go. Tossing barbed wire or razor wire on top kicks it up a notch. That makes it a real pain to climb over.

Razor barbed wire shows up in all kinds of heavy-duty spots—factories, border posts, army bases, jails, holding cells, government buildings. It fits right in with chain link fences at oil and gas sites. With tricks like these, companies keep their gear safe and the work flowing.

What Chain Link Fencing Brings to Oil and Gas Fields

How Chain Link Fences Hold Up Strong

Chain link fences stand out because they last and don’t give in easy. They’re built from good steel wires. Those wires pack a punch and stick around for years. They can take on wild winds or bangs without breaking down. Oil and gas fields get hit with crazy conditions. This kind of staying power keeps them reliable.

On top of that, chain link fences dodge rust with galvanization or PVC coating. These layers stretch out how long the fence lasts. They shield it from wet, chemicals, and nasty stuff floating around industrial zones.

Ways to Tweak Chain Link Fencing

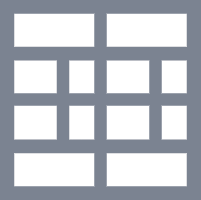

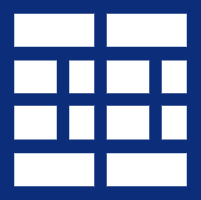

Chain link fencing bends to fit what oil and gas fields need. Companies can mix and match heights, mesh gaps, wire thickness, and coatings to match their safety plans. Here’s a quick look:

- Height: Goes from 0.5m to 6m, based on how much security they want.

- Mesh Gaps: Picks like 1″, 2″, 2-1/4″, and others.

- Wire Thickness: Runs between 1.2mm to 5mm for more muscle.

These options let folks shape their fences to handle whatever comes up.

Adding Barbed Wire and Razor Wire on Top

To beef up safety in oil and gas fields, chain link fences can get barbed wire or razor wire up high. Barbed wire throws in an extra hurdle. It’s a pain for anyone trying to hop over. Razor wire’s even meaner with its sharp edges. That stops trespassers cold.

Slapping these on doesn’t just make the fence tougher. It also fits the rules for risky spots like oil plants or pipelines.

Looking at Different Security Fences for Oil and Gas Fields

Chain Link Fence: A Solid Bet for Tight Security

Chain link fences are a hit for locking down oil and gas fields. They’re sturdy, easy to tweak, and don’t cost an arm and a leg. Made from strong steel wires, they hang tough against wind, bangs, and folks trying to bust them up. The open weave lets workers peek through and watch what’s going on.

One big plus is how they shrug off rust. With galvanized or PVC-coated steel wire, they laugh at wet, chemicals, and rough stuff in the air. That’s perfect for the wild weather at oil and gas spots. You can even jazz them up with privacy slats or barbed wire for more protection.

Curvy Welded Fence: What It’s Got Going

Curvy welded fences mix good looks with real grit. They work where safety and style both matter. These fences start with welded steel wires. Then they get bent into waves. That makes them stiffer. The shape looks sharp and holds strong.

They take on rough weather like champs—hot, cold, or soaking wet. Coatings like galvanization or PVC keep rust away for years. The curves also trip up anyone trying to climb over. That’s a security win.

358 High-Security Fence: Where It Shines

The 358 high-security fence is a beast. It’s built tough and hard to crack. The “358” tag comes from its setup: 3″ × 0.5″ × 8 gauge, or about 76.2mm × 12.7mm × 4mm (mesh gap × wire size). That tight weave stops climbers or cutters unless they’ve got fancy gear.

You see it at high-stakes places—jails, airports, factories. Now it’s popping up more in oil and gas fields. Hook it up with razor wire or cameras, and it’s a full-on safety net. Galvanization or powder coating keeps it kicking, even in nasty weather.

Setting Up and Keeping Field Fencing Going in Oil and Gas Fields

Smart Moves for Putting Up Chain Link Fences in Rough Spots

Getting chain link fences up in oil and gas fields takes some planning. Pick the right setup for what the place needs. Think about this:

- Height: Taller ones keep people out better.

- Mesh Gaps: Smaller holes mean tougher break-ins.

- Coating: Galvanized or PVC-coated wires dodge rust.

When putting it in, root the posts deep. Use concrete or something solid. That stops wind or crumbling dirt from tipping them over. Throw in tension bars at the sides. They keep the whole thing tight.

Keeping Fences in Shape for the Long Haul

Staying on top of upkeep keeps field fencing doing its job in oil and gas fields. Check it out often. Look for rust, loose bits, or bent posts. Hit rusted spots with anti-rust fixes quick. Swap them out if they’re too far gone.

Give the fence a scrub sometimes. That clears off dirt, junk, and chemical gunk that eats at it. Got barbed wire or razor wire up top? Check those too. Make sure they’re still good to go.

Beyond fixing stuff, toss in cameras or motion detectors. They juice up security without tearing up what’s already there.

FAQs

What fences fit oil and gas fields best?

Chain link fences, curvy welded fences, and 358 high-security fences top the list. They’re tough, easy to tweak, and handle rough days fine.

How do chain link fences measure up to others?

Chain link fences give you clear sight, low cost, and quick setup. Meanwhile, 358 high-security fences lock things down tighter but hit the wallet harder.

What’s the upkeep game plan for field fencing?

Look for damage or rust regular-like. Clean it up now and then. Fix stuff fast to keep it solid.

Can you tweak fencing to fit what you need?

Yep. AnPing JiaHui Wire Mesh Co., LTD hooks you up with custom fits. Pick your height, mesh size, coating, and extras like barbed wire.

For more on locking down your oil and gas fields with trusty fencing, hit up AnPing JiaHui Wire Mesh Co., LTD. They’re pros at whipping up field fencing systems, including Chain Link Fences.